About us

We are the experts in metal flow engineering.

We are a leading manufacturer of high-quality refractories, specializing in PCPF shapes, Flow Control Refractories, and Monolithic Refractories. Located in Gujarat, India, our proximity to seaports ensures efficient sourcing and exports.

Promoted by Chemical Engineers from IIT Mumbai and IIT Hyderabad, TIPL has a technology tie-up with IIT Hyderabad for testing, evaluation, and new product development

OUR PRODUCTS

FLOW CONTROL REFRACTORIES

Crucial components in steelmaking processes, regulating the flow of molten metal and enhancing casting precision.

CLOSED CASTING REFRACTORIES

Components that prevent contact of the molten metal with an open atmosphere, avoiding the reaction with oxygen to maintain the superior quality of the metal.

MONOLITHICS REFRACTORIES

Unshaped refractories are manufactured and tailor-made to suit the application.

PRECAST AND PREFIRED SHAPES

Special and critical shapes with alumina content ranging up to 97% alumina made from a choice of high-purity synthetic raw material.

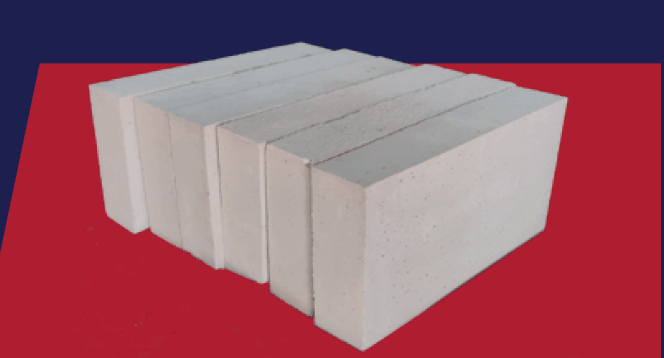

HIGH ALUMINA BRICKS

Contain upto 90% alumina and are used for lining of furnace or kiln, offering high-temperature, strength and chemical resistance

Why Thermoflyde?

Affordability

High quality at competitive prices.

Unmatched Quality

Rigorous testing and industry standards.

Expertise

Innovation based on industry experience.

Strategic Location

Optimal supply chain near major seaports

Customer-Centric Approach

Personalized service and support.

Sustainable Practices

Eco-friendly and energy-efficient production.